Things that have been made with a personal touch will continue to captivate people's interest. We keep ourselves occupied at work by decluttering and organizing our personal spaces, as well as making online purchases of footwear.

Each individual component of a vehicle, such as its on-board computer and electronic systems, its engines, its batteries, and a wide variety of other parts, possesses a level of complexity that is distinct from that of any other component. Examples of these types of components include: the on-board computer and electronic systems of the vehicle. These kinds of components include things like the on-board computer and electronic systems of the vehicle, as well as the engines, the batteries, and a wide variety of other parts and pieces. Because there are so many steps involved, it is not possible to print a car by simply pressing a button after the car has been designed. This is due to the fact that there are so many steps involved. To put it more succinctly, there are far too many steps involved.

As a result of a lack of preexisting infrastructure, design requirements, and federal safety regulations, there are a number of industry professionals who aluminum die casting parts are of the opinion that large-scale car personalization will be extremely difficult, if not impossible, to achieve in the next one hundred years. These professionals are of the opinion that this will be the case due to the fact that there are currently no regulations in place. This is as a result of the fact that there are presently no regulations that have been put into place that mandate how the design of automobiles must be. The automotive industry was one that Riley has worked in. Riley was employed in the field for an amount of time that was very close to equal to the total time period that was under consideration. It is anticipated that these kinds of technological advancements will be incorporated into vehicles of a more recent model.

However, Perry acknowledges that providing customers with an excessive number of options or open options only serves to confuse them, and that it is impossible to mass-customize a vehicle in order to cater to a specific market given how automobiles are manufactured. He also acknowledges that providing customers with an excessive number of options or open options only serves to confuse customers. According to John Kavala, a manufacturer of 3D printing, one of the reasons for this is that one does not need to produce enormous inventories in order to maintain low production costs. This is because one does not need to produce enormous inventories. On the other hand, because technological progress is occurring at such a rapid pace, the plausibility of this prediction is gradually increasing as a result of the rapid pace at which it is occurring. This is a result of the continual progress that is being made in technological fields. In point of fact, the rate of technological advancement is already significantly faster than the vast majority of people had anticipated it would be. This is contrary to the general consensus that technological progress will occur at a slower rate. This goes against the expectations that the vast majority of people had regarding the outcome of the situation.

Let's say for the sake of this example that we begin by constructing the car's body, and then we move on to constructing the additional parts that go on top of it. This would be the order in which we would complete these steps. It's possible that a manufacturer will develop a controlled CAD system that will let users add components to the chassis of a vehicle, but won't let them remove components that they've already added to the chassis. If this happens, it will be possible for users to add components to the chassis of a vehicle. If it is desired to do so, additional components like the windshield wipers, side mirrors, sunroofs, and other components of a similar nature can also be taken into consideration. This is a possibility that ought to be considered. According to Kavala, putting customers in a position where they can change the design of their vehicles puts them at risk and makes them vulnerable. This belief stems from the company's belief that this puts customers in a vulnerable position. This is due to the fact that allowing customers this capability puts them in danger.

The introduction of three-dimensional printing in a variety of different fields, including the field of materials, has resulted in the design and production of automobiles being subjected to significant shifts that have brought about significant changes. The study of materials is considered to be one of these fields. The client has provided a list of requirements, and in order to meet those requirements, this search is being carried out. The low unit yields that are typical in the aerospace industry are probably to blame for this situation. The aerospace industry is very focused on the benefits that can be gained from using 3D printing, particularly when it comes to designing products that are lighter in weight. In particular, the aerospace industry is very focused on using 3D printing to design products that are more aerodynamic. The aerospace industry in particular is very focused on making use of 3D printing in order to design products that are more aerodynamic. Particularly, the aerospace industry is placing a significant amount of importance on the zinc die casting manufacturer benefits that can be obtained through the application of technology known as 3D printing. In any event, this is not a component of the process that can be categorized as restrictive in any way. After all, a large number of design experts have stated that only a small percentage of customers actually know what they want, and that the majority of customers do not design something safe and practical for themselves to use in their own lives. This is due to the fact that most customers do not design something for themselves to use in their own lives. This is due to the fact that the overwhelming majority of clients do not design things that they intend to use in their own lives for the purpose of creating those designs. According to him, this preference remains constant regardless of the number of options they have.

In spite of the fact that members of the production generation almost certainly had their first experience with 3D technology at a young age, this does not necessarily mean that they have deeply ingrained expectations regarding the quality of automobiles and the safety of roadways. In fact, this is not necessarily the case. The overall form and texture of the design will be comparable to what one would anticipate in terms of both their appearance and their texture. This is because the form and texture of the design will be comparable to what one would expect. This is due to the fact that the form and texture of the design will be comparable to what an individual would anticipate. In addition, there is already a sizeable market zinc alloy die casting supplier for personalized accessories within the market for automotive software. This market is expected to grow in the near future. In the not-too-distant future, it is anticipated that this market will expand.

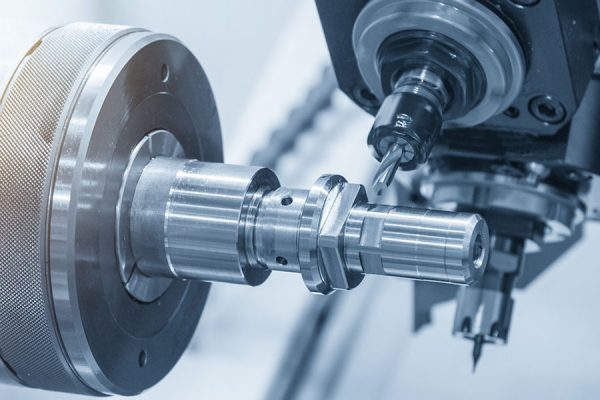

Is it possible that the costs of repairing vehicles will, at some point in the future, reach a point where they can be regarded as being more reasonable?It would appear that the answer to your question is going to be in the affirmative. Because it is possible to eliminate the costs that are associated with purchasing inventory and renting storage space, this is made possible through the utilization of technology that enables the printing of three-dimensional objects (3D printing). This is made possible due to the fact that it enables this to be made possible. Because of this, businesses now have the opportunity to cut costs. Manufacturing aftermarket parts in response to specific orders placed by customers will be a possibility for companies that sell aftermarket parts. Traditional manufacturers of automobiles are gradually coming around to the idea that 3D printing may be useful to their industry as well. This shift is occurring because of the Sandblasting Services potential benefits that 3D printing could offer. This shift is taking place as a direct result of the potential advantages that 3D printing might provide. They want to find a way to use this technology to replicate the functionality of traditional metal tools, which are notoriously difficult to acquire and prohibitively expensive to manufacture. They want to do this as cheaply as possible. This is the goal that they prioritize above all others.